MANAHAWKIN – The US Nuclear Regulatory Commission held a public hearing at The Holiday Inn in Manahawkin to discuss the current state and the future of the Oyster Creek Generating Station with concerned residents.

Members of the NRC were present to discuss the process of decommissioning the plant and answer any questions that anyone might have. What was intended to be a more formal public hearing became a more relaxed atmosphere where people could walk up to NRC members and ask questions or take a stroll around the room to look at the informative posters.

Exelon Generation, the company that owns Oyster Creek, announced near the end of January 2018 that the plant will be closing its doors at the end of this year, around October. It was originally slated to close December 2019.

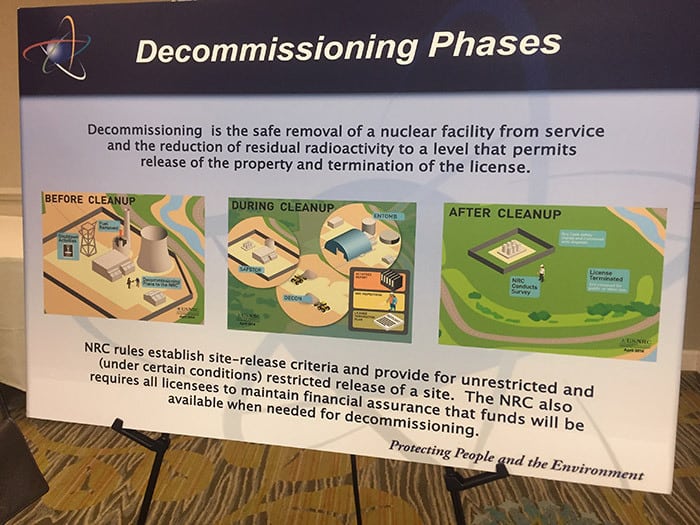

Following the shutdown of the station, Exelon and the NRC will begin the process of decommissioning. According to the NRC, decommissioning is defined as, “the safe removal of a nuclear facility from service and the reduction of residual radioactivity to a level that permits release of the property and termination of the license.”

The NRC laid out a very brief Decommission Timeline that begins with the shutdown of the plant, which can take up to two years. During this time, the licensee submits their decommissioning plans to safely shut down and store spent waste from the facility.

According to the NRC, Oyster Creek’s decommissioning plans will utilize the SAFESTOR strategy. This is known as “”deferred dismantling:” a nuclear facility is maintained and monitored in a condition that allows the radioactivity to decay,” according to the NRC website.

Following this decaying process, spent fuel is transferred into dry cask storage; then follows decontamination and dismantling of the facility. This entire process can take up to 60 years.

“They take years and years to build and it takes years and years to transition,” out of operation, said Matt Fannon, resident inspector at the Oyster Creek site.

Fannon noted that even though the site will not be in operation during decommissioning, there will still be plenty of routine checks and monitoring on the plant.

Matt Young, Senior Resident Inspector at the NRC, said that the end goal for when the site is decommissioned is that everything in the reactor building, all of the spent fuel, will be transferred into these dry cask storage units.

“There’s a metal cask that it goes in, then they weld it all up, then they put it in a concrete cask,” and in a concrete facility, said Young about the spent fuel. “We come out and inspect that.”

Young explained that the dry cask storage facility is not new technology.

“Most every sizeable power plant has a storage facility because there is no long term storage facility for all of them,” said Fannon.

Before spent fuel is stored in these dry cask units, it needs to cool, which is a process that can take up to five years, according to Bruce Watson, chief of the Reactor Decommissioning Branch of the NRC.

“When the fuel is removed from the reactor it’s, I’ll say hot…after about 300 days to a year or year and a half, it will be very cool compared to what it was when it came out,” said Watson. “After that point, it’ll continue to cool.” This continued cooling can take up to five years, he added.

When the decay heat of the fuel reaches a lower point, it can be transferred into the dry storage container, said Watson, which has no water. “It doesn’t need any additional cooling other than the ambient air.”

This cooling process prior to dry cask storage is what NRC calls SAFESTOR.

The dry cask storage facility will be on the premises of the reactor building so as not to transfer spent fuel any significant distance. It will remain here indefinitely, as there is no long term storage facility outside of this in place already.

This decommissioning process has not yet begun as the plant is still operating until the end of its current operating cycle in October.

Following the shutdown of the plant, Young noted that residents surrounding the plant will still receive yearly calendars and updated information on the site.